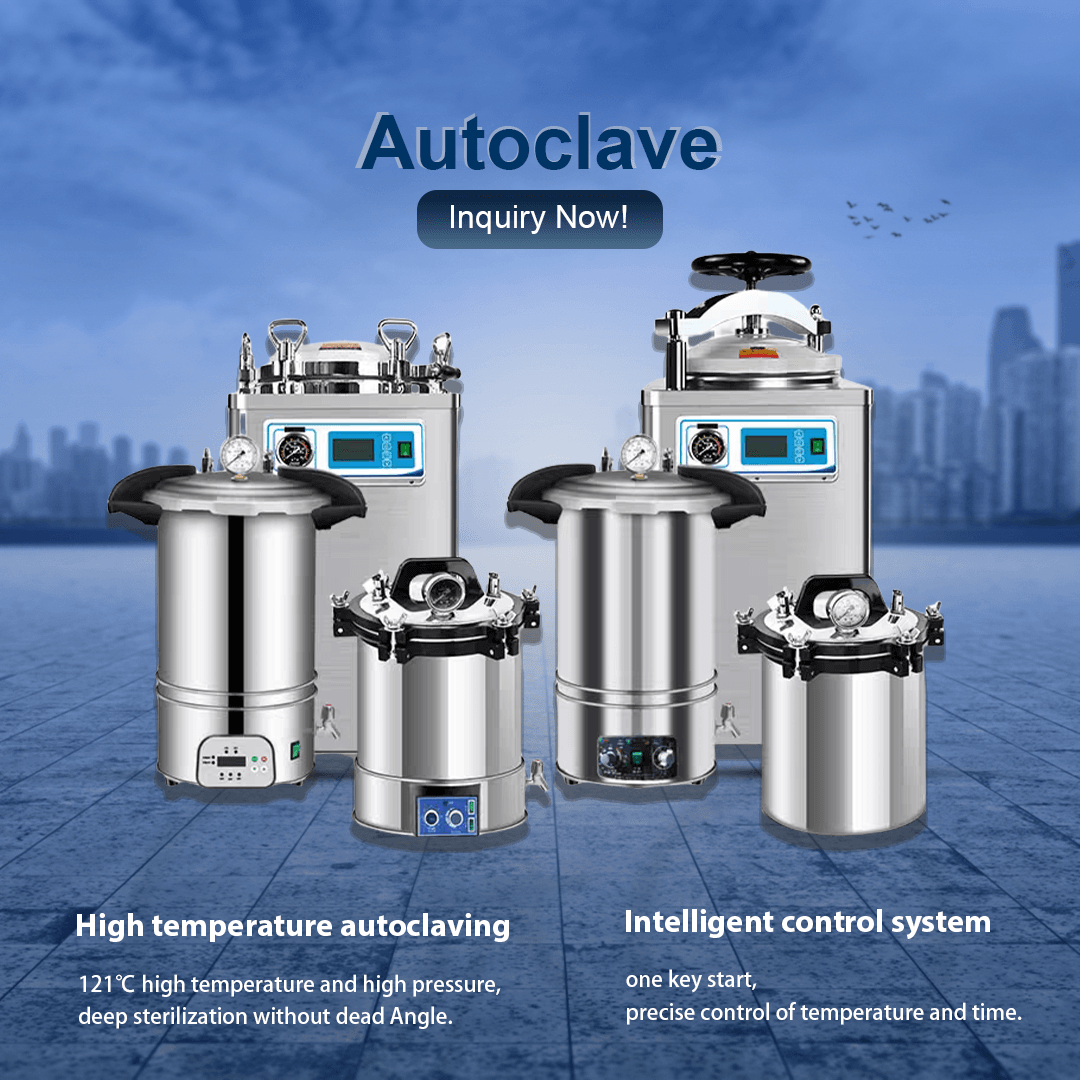

Vertical autoclaves function as steam sterilizers equipped with vertical chambers. The vertical autoclave uses high-pressure saturated steam to sterilize medical tools and laboratory instruments alongside other materials. Vertical autoclaves provide more compact designs that make them suited for use in space-limited facilities.

This compact autoclave design saves space and fits well in facilities with limited room.

The autoclave achieves high sterilization efficiency by applying steam pressure to effectively destroy bacteria and viruses together with spores.

The operation of this device requires minimal effort because of its intuitive control system.

High-quality stainless steel provides a long-lasting construction for this product.

The equipment offers versatile sterilization capabilities for different materials such as surgical instruments, glassware, and textiles.

The function of vertical autoclaves is based on the method of steam sterilization to achieve sterilization. Here’s how the process works:

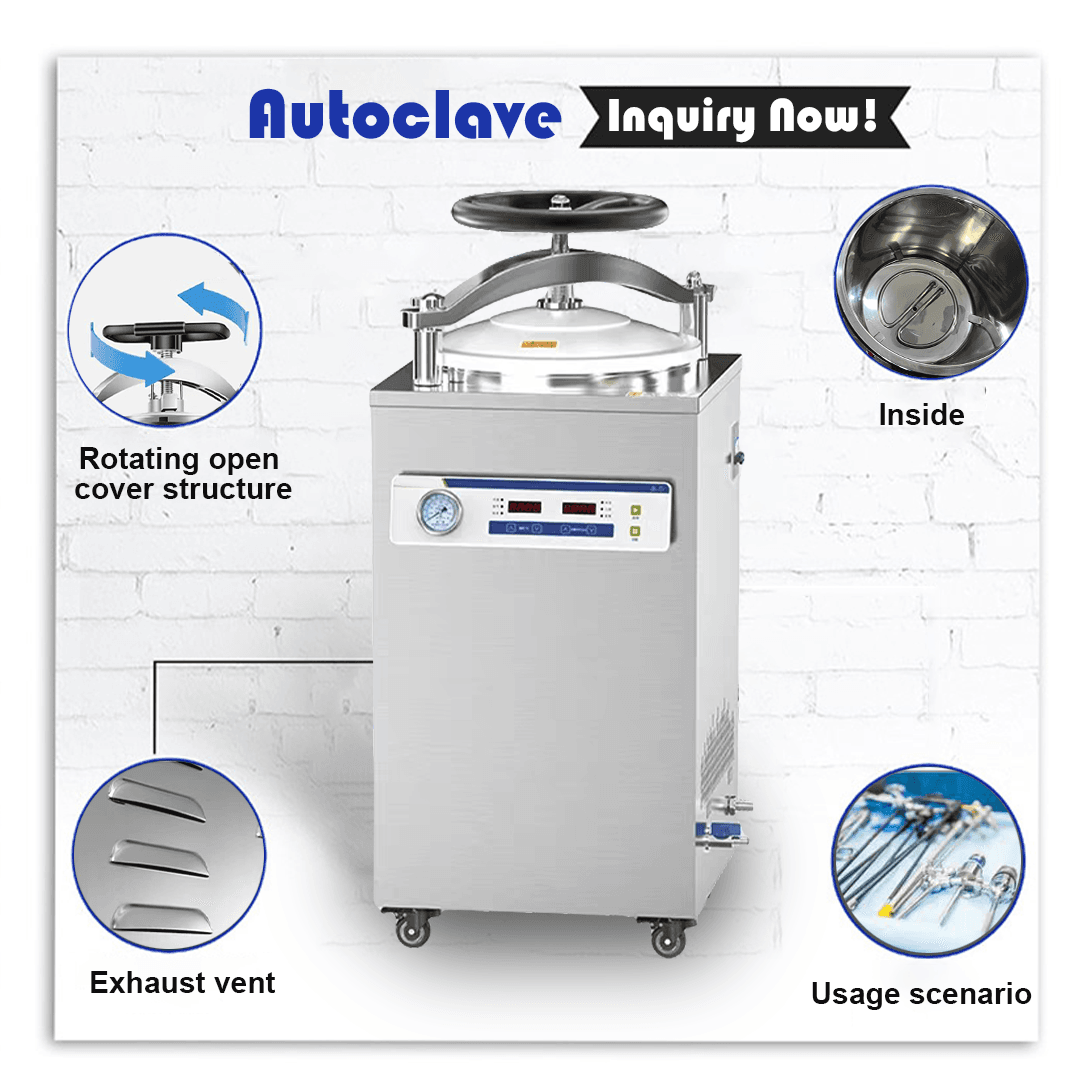

Loading: The chamber receives both instruments and materials for sterilization.

Sealing: The chamber remains closed until it forms an air-tight space.

Heating: The autoclave generates steam by heating water which undergoes pressurization.

Sterilization: The high-pressure steam infiltrates materials to eliminate all microorganisms.

Cooling: Once sterilization is complete the chamber pressure reduces and items inside cool down.

Multiple industries utilize vertical autoclaves for sterilization needs.

Medical Facilities: Vertical autoclaves are used in medical facilities to sterilize surgical instruments along with dressing materials and additional equipment.

Laboratories: Sterilizing glassware, culture media, and waste materials.

Pharmaceuticals: Ensuring the sterility of production equipment.

Veterinary Clinics: Sterilizing instruments used in animal care.

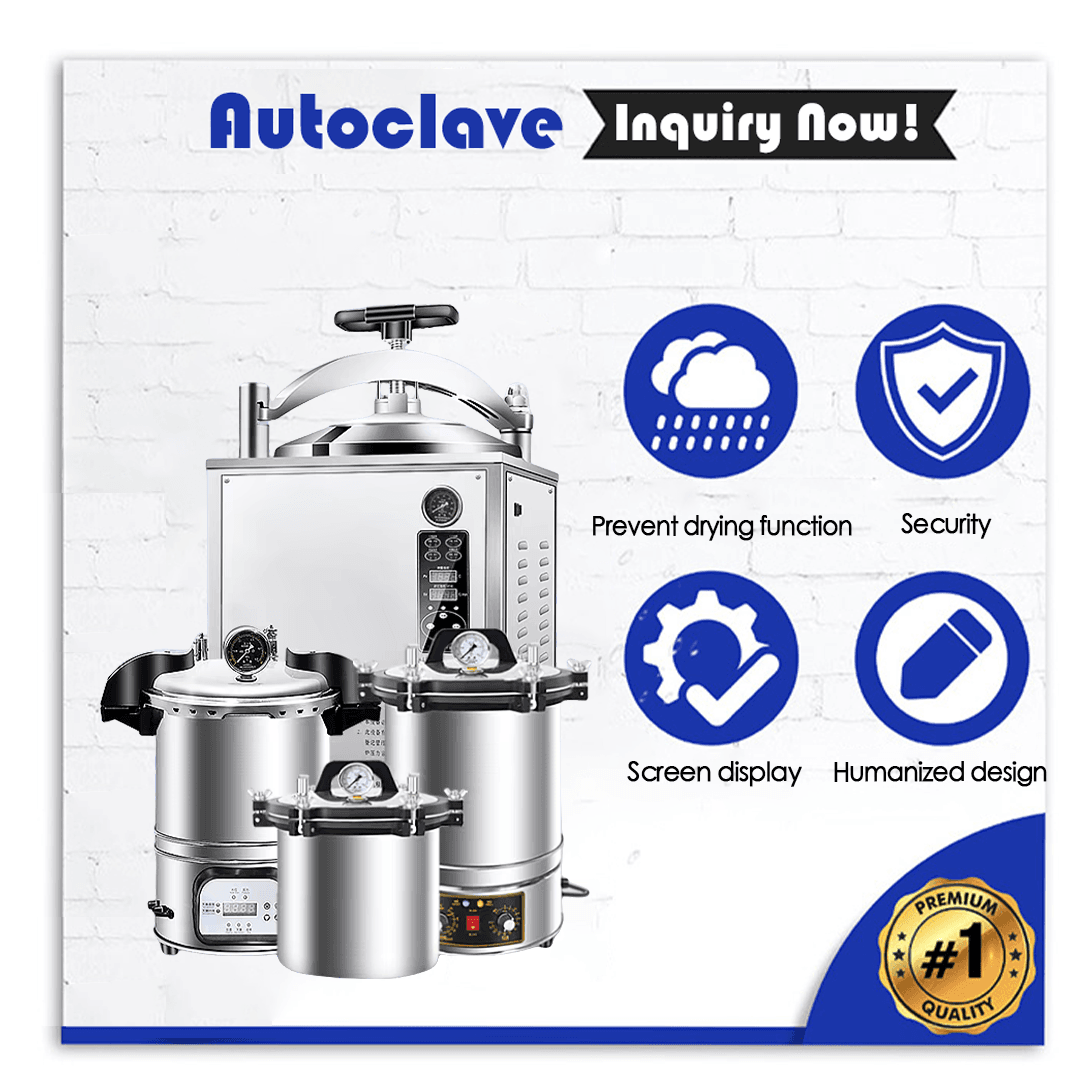

Cost-Effective: Vertical autoclaves provide a more economical sterilization solution than horizontal autoclaves making them perfect for facilities with medium to small capacity needs.

Energy Efficient: This autoclave achieves high sterilization standards while using less energy.

Space-Saving: Compact design fits into tight spaces.

Reliable Sterilization: Ensures complete elimination of microorganisms.

Ease of Maintenance: This equipment allows extended operation periods while requiring very little maintenance.

Select a vertical autoclave by evaluating these important criteria:

Capacity: Select a size that aligns with your sterilization requirements.

Material: Opt for stainless steel chambers for durability.

Safety Features: Choose vertical autoclaves with advanced safety mechanisms such as pressure relief valves and temperature controls.

Compliance: Ensure the autoclave meets international sterilization standards.

Warranty and Support: Select a manufacturer that provides dependable service after your purchase.

Medical equipment distributors, resellers, and buyers rely on vertical autoclaves as critical tools. The combination of compact size, high efficiency and versatile functionality establishes vertical autoclaves as the preferred option for medical and laboratory sterilization requirements. Knowing vertical autoclave features and applications helps you make well-informed choices while maintaining optimal sterility standards for your clients.

For more information or to inquire about high-quality vertical autoclaves, contact us today at:

Email: inquiry@shkeling.com

WhatsApp: Click to Chat

Website: https://autoclaveequipment.com/

Vertical autoclaves have a top-loading design, making them compact and space-saving, while horizontal autoclaves are larger and designed for higher capacity sterilization.

Vertical autoclaves can sterilize surgical instruments, glassware, textiles, and waste materials, among others.

Yes, vertical autoclaves are designed to consume less energy while maintaining high sterilization standards.

Regularly clean the chamber, check the gaskets, and ensure the water supply is free of impurities. Always follow the manufacturer’s maintenance guidelines.

Absolutely! Their compact design makes them ideal for facilities with limited space.

For further inquiries or product details, feel free to contact us via:

Email: inquiry@shkeling.com

WhatsApp: Click to Chat

Website: https://autoclaveequipment.com/

Healthcare facilities must adhere to rigorous hygiene and sterilization standards without exception. Medical equipment distributors and procurement professionals must understand the tools that maintain standards to deliver value to healthcare

Maintaining sterile medical tools and equipment stands as the most important practice for preventing infections and ensuring patient safety in healthcare settings. Medical equipment distributors along with dealers and procurement

The fast-paced healthcare sector operates under strict regulations which demand that sterility maintenance stands as a primary concern to protect patient safety and ensure compliance with operational standards. Medical equipment

Sterilization equipment serves as an essential tool in healthcare settings to maintain cleanliness standards and protect patients. Medical equipment distributors together with dealers and procurement specialists need to know the

Autoclaves serve as essential components of sterilization processes in healthcare facilities through high-pressure steam to destroy pathogens on medical instruments and other materials. Medical equipment distributors and procurement specialists must

Healthcare environments must prioritize sterilization because it protects patients and staff by removing infectious pathogens from medical devices and materials. The autoclave stands out as one of the best tools