Distributors and resellers as well as procurement specialists need to understand both the price range and types of autoclave heating coils to manage costs while maintaining sterilization efficiency. This article delivers detailed information about heating coil pricing and types alongside maintenance tips to guide your purchasing decisions.

Heating coils serve an essential function within sterilization systems by transforming electrical power into heat energy. The generated heat transforms into steam inside the autoclave chamber to eradicate bacteria, viruses and other microorganisms. This section outlines the key reasons heating coils are critical components for effective sterilization processes.

The sterilization cycle maintains consistent temperature levels through the operation of heating coils.

Heat distribution that remains uniform across the sterilization chamber prevents incomplete sterilization processes and meets hygiene regulations.

Designs of high-quality heating coils focus on minimizing energy consumption which leads to lower operational expenses.

Energy-efficient coils deliver perfect performance while reducing power usage.

High-quality heating coils provide durability that minimizes equipment failure and operational downtime.

Uninterrupted sterilization processes in medical and laboratory settings depend on dependable coils.

Different autoclave models require heating coils that come in multiple designs to match their specific capacities.

Selecting an appropriate coil helps maintain compatibility while optimizing operational efficiency.

The cost of autoclave heating coils depends on their size as well as the material and design specifications. Below is a general price breakdown:

Price Range: $50 – $150

This heating coil design accommodates autoclave models that handle capacities between 10 and 50 liters.

These heating coils are appropriate for small clinics as well as laboratory and dental office environments.

Price Range: $150 – $300

This heating coil functions with medium-sized autoclaves that hold between 50 and 100 liters.

The heating coil application best suits hospitals, veterinary clinics and research laboratories.

Price Range: $300 – $800+

The heating coils are specifically engineered for use with large autoclaves which have capacities greater than 100 liters.

These heating coils work effectively in both industrial sterilization settings and large medical facilities.

Multiple types of heating coils exist which provide distinct benefits. The following text presents a comparison between common types of heating coils.

Price Range: $150 – $400

The coils provide durability alongside corrosion resistance which makes them suitable for high-temperature applications.

Stainless steel heating coils provide extended operational life while requiring minimal upkeep and delivering effective heat transfer functions.

The initial investment required for these coils surpasses that of other materials.

Price Range: $100 – $300

Features: Excellent heat conductivity and affordable pricing.

Copper heating coils provide both cost efficiency and performance benefits for autoclaves ranging from small to medium sizes.

Disadvantages: Susceptible to corrosion over time.

Price Range: $200 – $500

This product consists of heat-resistant alloy materials that serve demanding applications.

The heating coils feature superior durability alongside resistance to extreme temperature variations.

Disadvantages: Higher cost and limited availability.

Heating coils require proper maintenance to remain efficient and durable over time. Below are some practical tips:

Use a soft brush or cloth to eliminate mineral deposits and debris from the coil surface.

Using distilled water in the autoclave helps prevent mineral build-up.

Perform routine inspections of the coil to identify wear patterns and detect any corrosion or crack developments.

Damaged coils should be replaced immediately to prevent equipment breakdown.

When the autoclave heats up slowly or generates inconsistent steam, you should check the coil for potential problems.

A decline in performance could suggest that coil replacement is necessary.

Follow the maintenance schedule provided by your autoclave manufacturer.

Implement replacement coils that are compatible to maintain proper equipment operation.

Buy autoclave coils constructed from long-lasting materials such as stainless steel or specialized heat-resistant alloys.

High-quality coils reduce long-term maintenance costs.

The heating coils within autoclaves play a crucial role because they affect both the performance efficiency and the equipment reliability. The knowledge about heating coil cost ranges and types along with maintenance advice enables distributors and procurement experts to make better purchasing choices.

By investing in high-quality coils and maintaining them properly, you can ensure uninterrupted sterilization and reduce long-term costs. For more information on sterilization equipment pricing, check out our next article: Sterilizer Cost Overview.

If you have any questions or need assistance, contact Keling Medical using the details below. Our team is ready to help you find the perfect heating coil for your autoclave.

The average price ranges from $150 to $400, depending on the size and material of the coil.

Heating coils should be replaced when they show signs of wear, reduced performance, or damage. Regular inspections can help determine replacement needs.

Yes, stainless steel coils are durable, corrosion-resistant, and offer efficient heat transfer, making them a cost-effective choice in the long run.

Copper coils are generally suitable for small to medium-sized autoclaves. For large autoclaves, alloy or stainless steel coils are recommended.

Using distilled water in the autoclave and cleaning the coil regularly can prevent mineral buildup and extend its lifespan.

For more information or to request a quote, contact us today:

Email: inquiry@shkeling.com

WhatsApp: Click to Chat

Website: https://autoclaveequipment.com/

Let us help you find the perfect heating coil solution for your autoclave!

Healthcare facilities must adhere to rigorous hygiene and sterilization standards without exception. Medical equipment distributors and procurement professionals must understand the tools that maintain standards to deliver value to healthcare

Maintaining sterile medical tools and equipment stands as the most important practice for preventing infections and ensuring patient safety in healthcare settings. Medical equipment distributors along with dealers and procurement

The fast-paced healthcare sector operates under strict regulations which demand that sterility maintenance stands as a primary concern to protect patient safety and ensure compliance with operational standards. Medical equipment

Sterilization equipment serves as an essential tool in healthcare settings to maintain cleanliness standards and protect patients. Medical equipment distributors together with dealers and procurement specialists need to know the

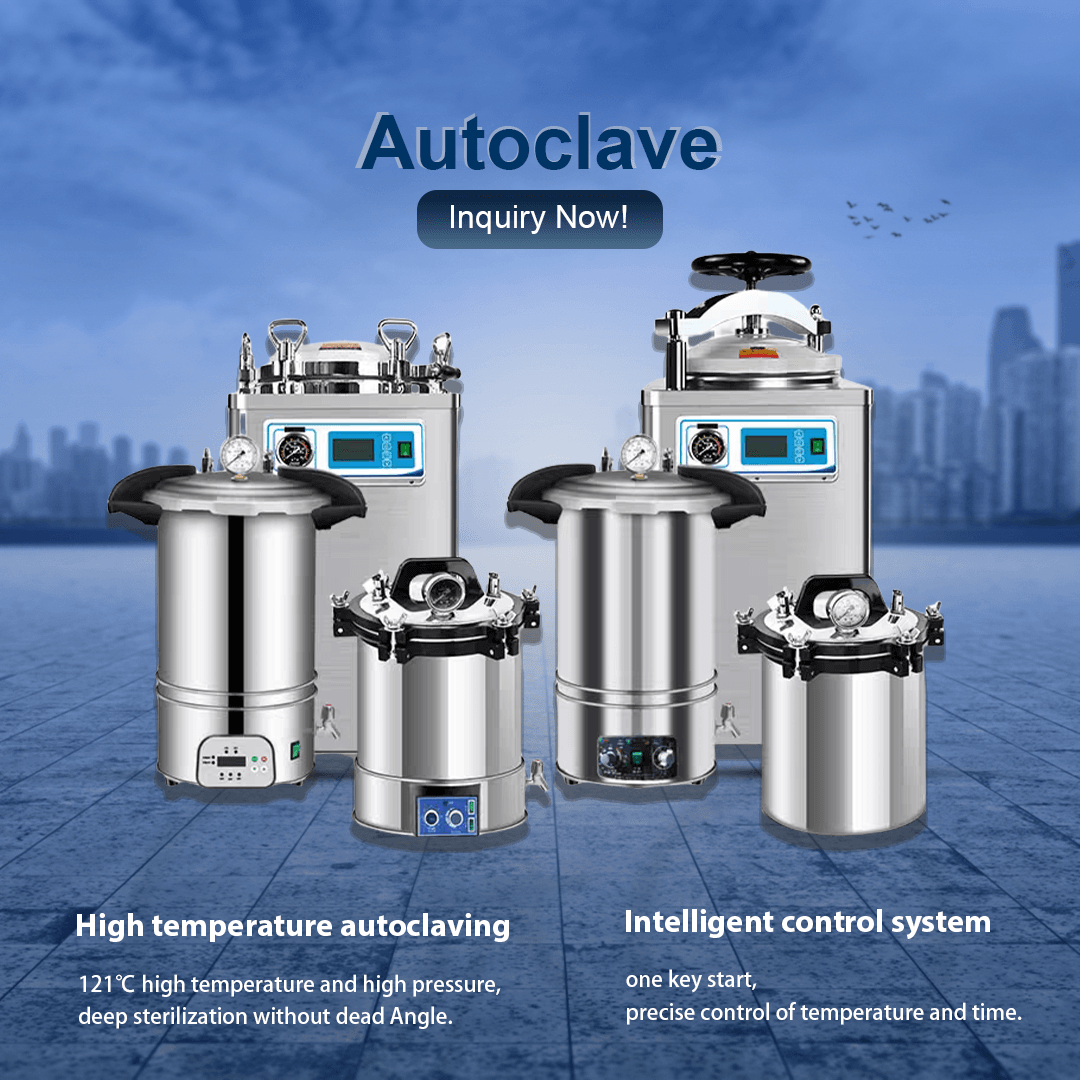

Autoclaves serve as essential components of sterilization processes in healthcare facilities through high-pressure steam to destroy pathogens on medical instruments and other materials. Medical equipment distributors and procurement specialists must

Healthcare environments must prioritize sterilization because it protects patients and staff by removing infectious pathogens from medical devices and materials. The autoclave stands out as one of the best tools