The article examines how hospital sterilizers work alongside autoclave hospital systems and medical autoclaves to maintain infection control. We will examine modern sterilizer machines’ benefits for hospitals while offering guidance on choosing appropriate equipment.

Hospital sterilizers function as specialized equipment that eliminates contaminants from medical instruments and equipment while also sterilizing hospital waste. Hospital sterilizers serve as critical tools for infection control while maintaining adherence to rigorous healthcare regulations.

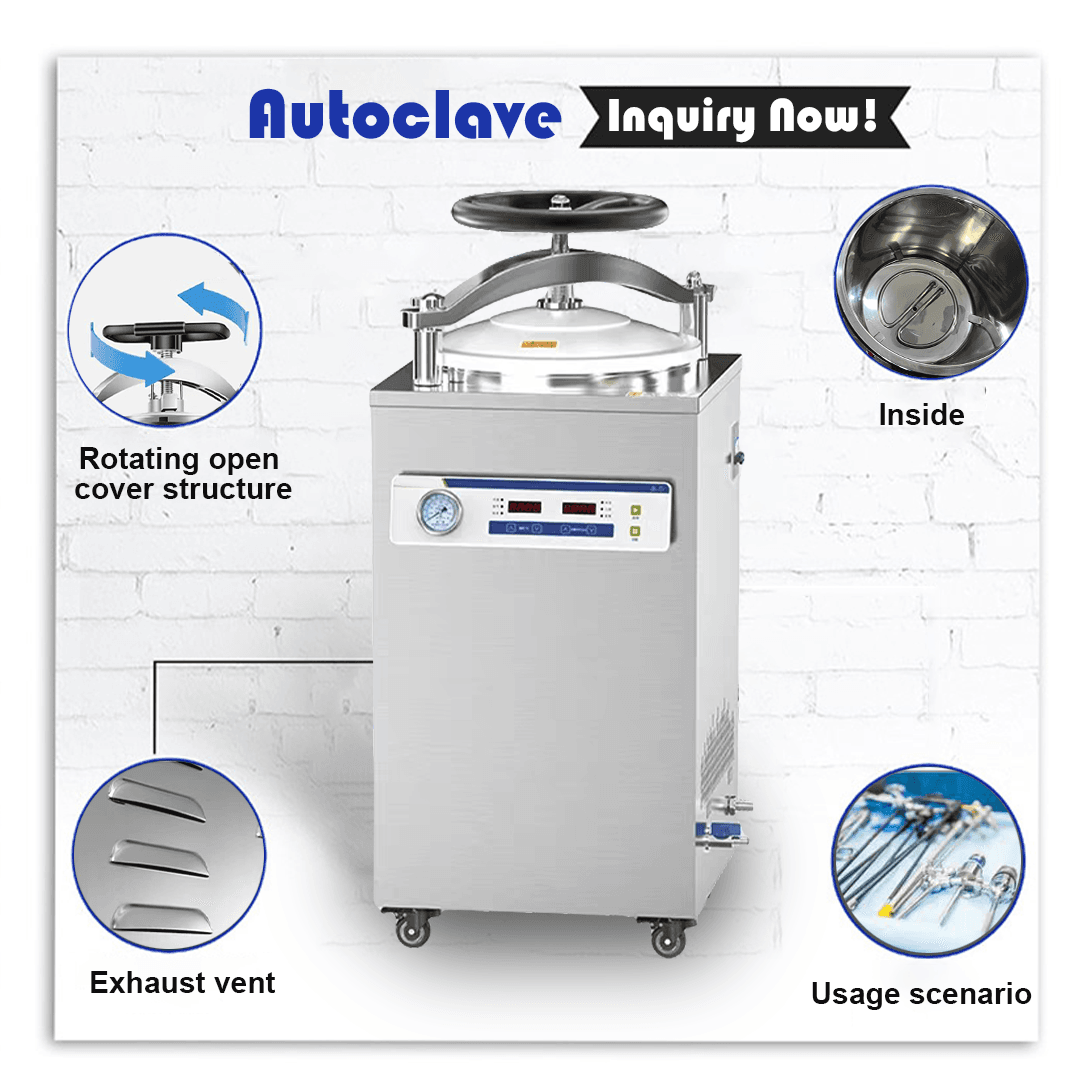

Autoclave hospital systems stand out as the most popular choice among sterilizer types because of their superior efficiency combined with reliable performance. These machines reach high levels of sterilization through the use of high-pressure saturated steam (health steam) to destroy bacteria, viruses, and spores which makes them perfect for hospital and laboratory environments.

Hospitals rely on autoclaves as their main sterilization equipment. The autoclave achieves high temperatures through steam under pressure that destroys microorganisms. Hospital autoclave systems are available in multiple sizes and designs which makes them appropriate for large hospitals as well as small clinics.

The specific design of medical autoclaves enables them to sterilize surgical instruments along with laboratory tools and additional medical equipment. The machines perform full sterilization of each item in accordance with top safety standards.

Hospitals commonly select steamer sterilizers as their preferred equipment for sterilization purposes. Steam sterilizers function through steam to clean equipment and serve as the preferred choice for delicate instruments needing gentle yet powerful sterilization.

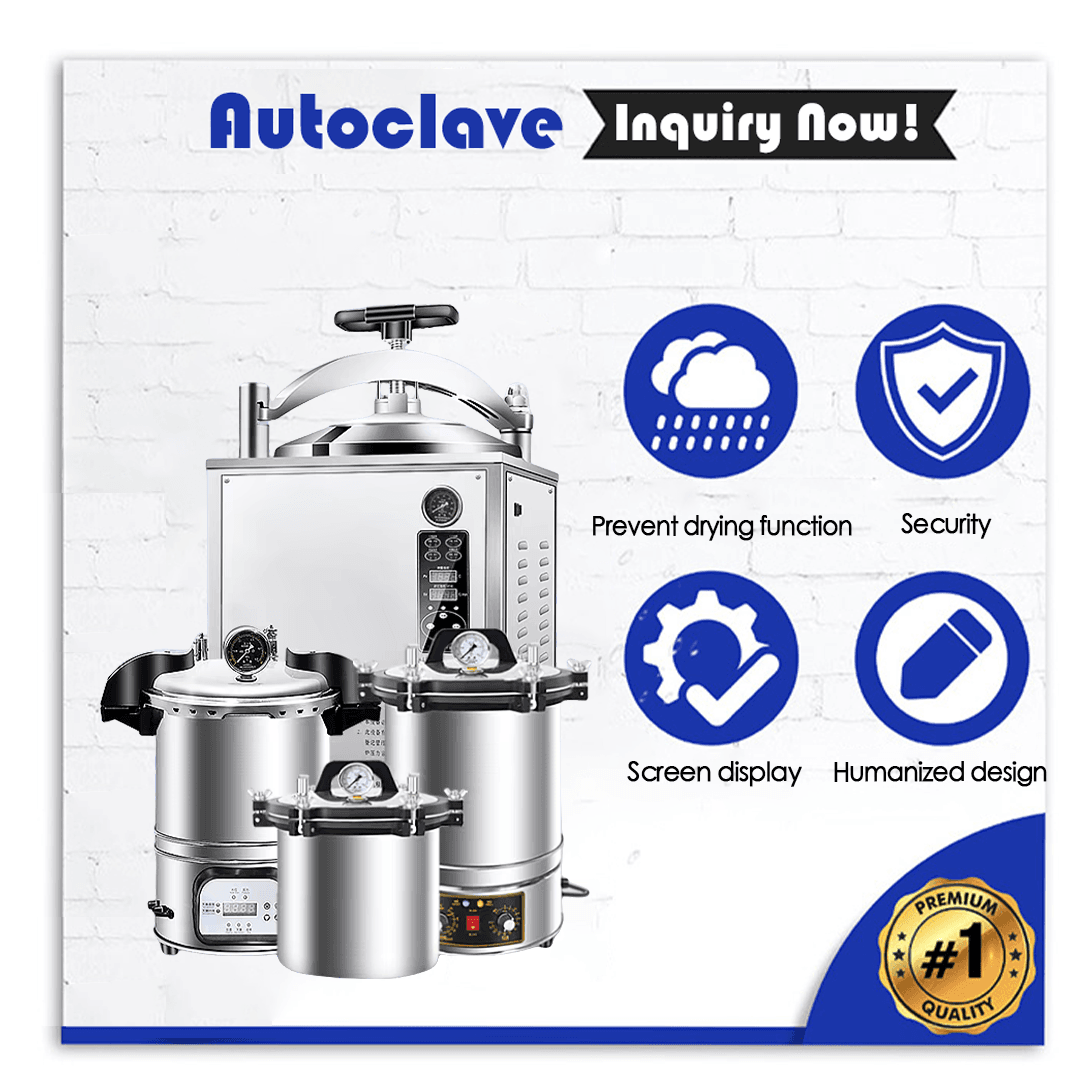

Originally intended for smaller applications home autoclaves have become increasingly popular in medical clinics and laboratory settings. Compact sterilizers suit facilities that have restricted spatial availability or reduced sterilization requirements.

Castle autoclaves stand out because of their long-lasting build and superior operational performance. These machines find their application mainly in demanding environments where dependable performance is essential.

Hospital autoclave systems sterilize medical equipment through the application of high-pressure steam. The process involves several steps:

Laden: Instruments are placed inside the autoclave chamber.

Heizung: Upon sealing the chamber steam is injected to elevate the temperature to necessary sterilization ranges of 121–134°C.

Sterilisation: All microorganisms are destroyed when exposed to high temperature and pressure.

Kühlung: The pressure inside the chamber is reduced before allowing the sterilized items to cool down.

Entladen: The sterilized instruments undergo removal from the chamber and are stored until needed.

By removing pathogens from all items the process proves autoclaves are essential tools in sterilization of hospital and laboratory environments.

Hospital sterilizer machines require consideration of key features when making a selection.

Wirkungsgrad: The design of modern hospital sterilizers promotes quick and complete sterilization while minimizing operational interruptions.

Kapazität: Select the proper sterilizer for your facility whether it’s a small home autoclave or a large hospital system.

Dauerhaftigkeit: The use of high-quality materials like stainless steel enables sterilizers to maintain sustained performance.

Benutzerfreundlichkeit: The combination of easy-to-use interfaces with automated processes decreases error rates during operation.

Sicherheitsmerkmale: Users and equipment receive protection from advanced safety features which include pressure release valves and temperature monitors.

Autoclaves remove pathogens from equipment which lowers healthcare-associated infection risks.

Sterilizers in hospitals achieve strict international sterilization criteria which guarantee both safety and dependability.

The substantial upfront investment pays off because the prolonged advantages of decreased infection rates paired with extended equipment life exceed the initial costs.

Autoclaves can sterilize everything from surgical instruments to laboratory tools which makes them both versatile and indispensable.

Contemporary autoclaves focus on environmental sustainability by decreasing their water and energy usage while achieving energy efficiency.

Selecting the appropriate sterilizer machine for hospital operations demands careful analysis of your facility’s specific needs.

The selection process for a sterilizer for hospital use demands a thorough evaluation of your facility’s specific requirements. Here are some tips:

Assess Your Requirements Analyze both the quantity and categories of items that require sterilization. Big hospitals need high-capacity autoclaves for effective sterilization while small clinics find compact home autoclaves more suitable for their needs.

Check Compliance The sterilizer must comply with international standards and certifications required for hospital and laboratory sterilization use.

Evaluate Features Select autoclaves that offer programmable cycles along with digital displays and safety features.

Consider Maintenance Opt for a sterilizer that demands minimal maintenance and comes with accessible support services.

Haushalt Quality and reliability should be prioritized over cost to achieve lasting value.

Sterilization technology continues to develop with new advancements and improvements. Here are some recent innovations:

IoT-Integration Current hospital sterilizers incorporate IoT technology which permits operators to monitor and control devices from a distance.

Energie-Effizienz Recent hospital sterilizer models have been engineered to decrease water and energy usage which enhances their sustainability.

Advanced Safety Features The incorporation of automatic shut-off and pressure monitoring into safety systems guarantees secure operation.

Customizable Cycles Users can now customize sterilization cycles with modern sterilizers designed to match particular requirements.

A hospital autoclave is designed for high-capacity sterilization in demanding environments, while a home autoclave is smaller and suitable for clinics or laboratories with lower sterilization needs.

A steamer sterilizer uses steam to sterilize equipment. It is ideal for delicate instruments that require gentle yet effective sterilization.

Castle autoclaves are known for their durability and efficiency, making them a reliable choice for high-demand environments.

While medical autoclaves are versatile, certain materials may require specialized sterilization methods. Always check the manufacturer’s guidelines.

Regular maintenance is essential to ensure optimal performance. Follow the manufacturer’s recommendations for maintenance schedules.

Hospital sterilizers, including autoclaves, are essential in maintaining safety and hygiene in healthcare and laboratory settings. From large autoclave hospital systems to compact home autoclaves, these machines play a crucial role in infection control and compliance with international standards.

For distributors, resellers, and procurement professionals, understanding the features and benefits of hospital sterilizers is key to making informed decisions. By investing in high-quality sterilizer machines, you can ensure the safety of patients and staff while optimizing operational efficiency.

For more information about hospital sterilizers or to explore our range of autoclave solutions, please contact us:

E-Mail: inquiry@shkeling.com

WhatsApp: +8618221822482

Website: https://autoclaveequipment.com/

Lassen Sie uns Ihnen helfen, die perfekte Sterilisationslösung für Ihre Einrichtung zu finden!

Sterile Bedingungen sind in Zahnarztpraxen nach wie vor von grundlegender Bedeutung, um die Patienten zu schützen und gleichzeitig die Gesundheitsvorschriften zu erfüllen. Zahnkliniken setzen Autoklaven ein, um ihre Instrumente und Geräte zu sterilisieren und gefährliche Mikroorganismen abzutöten.

Die Aufrechterhaltung der Sterilität von zahnärztlichen Instrumenten und Ausrüstungen ist nach wie vor von entscheidender Bedeutung für den Schutz der Patienten und die Einhaltung von Gesundheitsstandards. Zahnärztliche Sterilisatoren sind wichtige Geräte, die gefährliche Mikroorganismen aus zahnmedizinischen

Im zahnmedizinischen Bereich sind sterile Umgebungen erforderlich, um die Sicherheit der Patienten zu gewährleisten und die Gesundheitsvorschriften zu erfüllen. Dentalautoklaven dienen als spezielle Sterilisationsmaschinen, die schädliche Mikroorganismen auf zahnmedizinischen Geräten zerstören

Das Gesundheitswesen und die verarbeitende Industrie benötigen sterile Umgebungen, um die Sicherheit zu gewährleisten und die Industrienormen zu erfüllen. Industrielle Autoklaven dienen als hochentwickelte Sterilisationsgeräte, die Hochdruckdampf zur Desinfektion medizinischer Produkte verwenden.

Die Aufrechterhaltung einer sterilen Umgebung ist unter anderem im Gesundheitswesen und in der verarbeitenden Industrie für die Sicherheit und die Einhaltung von Vorschriften unerlässlich. Industrielle Autoklaven sind hochentwickelte Sterilisationssysteme, die Hochdruckdampf zur Ausrottung von

Der Gesundheitssektor verlangt vor allem effiziente Sterilisationsmethoden. Große Autoklaven bewahren die Sterilität von medizinischen Instrumenten und Geräten, indem sie gefährliche Mikroorganismen abtöten. Diese Geräte bewältigen erhebliche Mengen an