The specialized sterilization device known as a large autoclave uses high-pressure steam to sterilize numerous medical instruments and equipment together with other materials. Large autoclaves sterilize equipment by heating steam beyond 100°C (212°F) which destroys bacteria viruses spores and other pathogens. The primary application of these autoclaves is in environments that require rapid sterilization of substantial amounts of items.

Large autoclaves are vital for several reasons:

High-throughput autoclaves process multiple items at once which makes them suitable for fast-paced healthcare settings where both time efficiency and productivity matter.

High-pressure steam in large autoclaves achieves complete sterilization which helps to minimize healthcare-associated infections (HAIs).

Healthcare facilities have to follow strict sterilization protocols to remain in accordance with regulatory standards. Large autoclaves serve as dependable solutions to reach compliance standards.

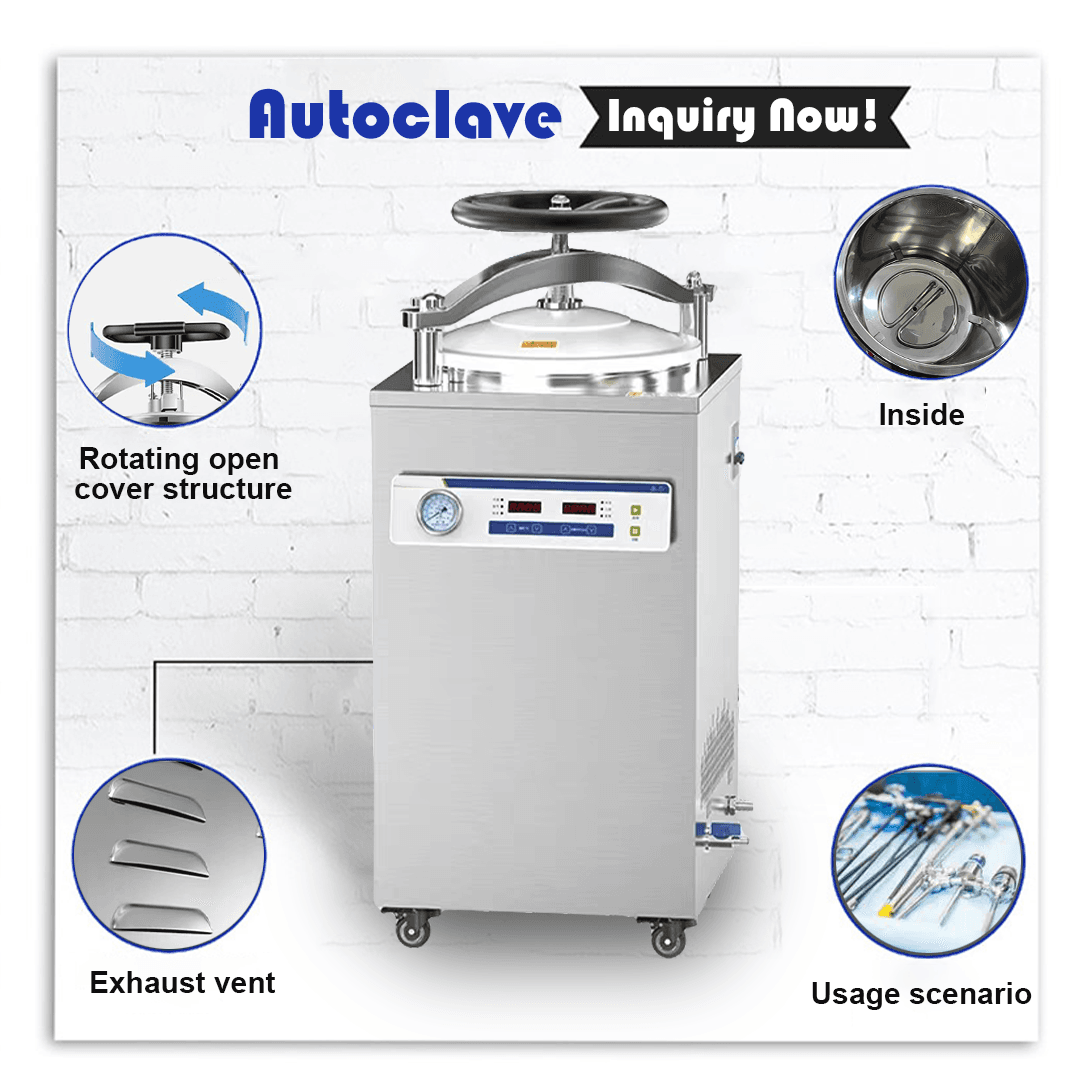

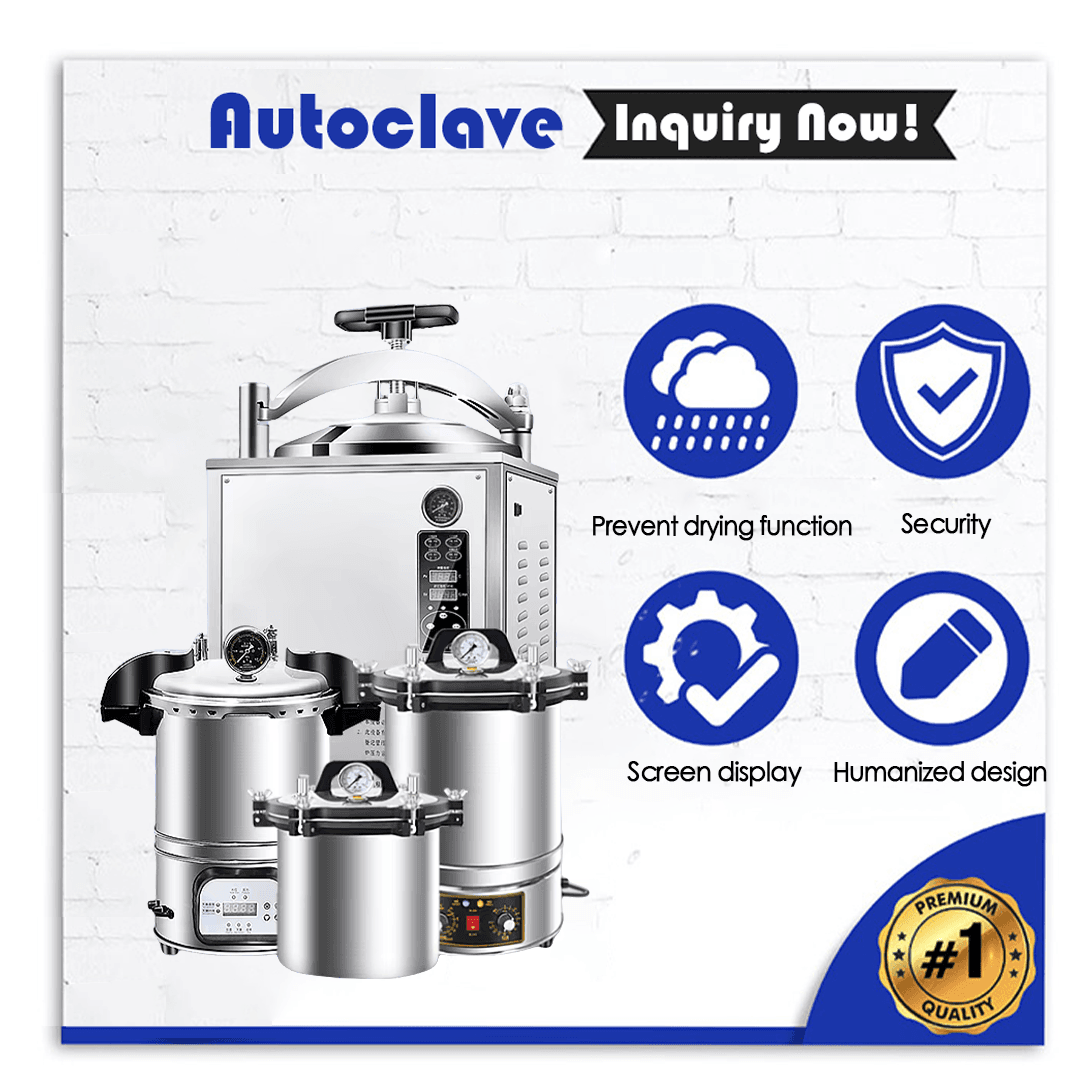

Vertical autoclaves contain a vertical chamber which enables effective steam circulation throughout the device. Vertical autoclaves find frequent application in hospitals and laboratories where room availability is restricted. These autoclaves can effectively sterilize liquid and solid materials along with wrapped items.

Horizontal autoclaves contain horizontal chambers that allow for more loading space. Horizontal autoclaves offer an ideal solution for sterilizing large instruments and substantial batches of materials. Surgical departments and research facilities frequently employ horizontal autoclaves for sterilization processes.

Double-door autoclaves are made to support environments that require high contamination control standards. The double-door autoclaves use separate entry points for loading and unloading which prevents sterilized materials from contacting unsterilized spaces. Sterile processing departments benefit significantly from this design approach.

Steam-flush pressure pulse autoclaves combine steam flushes with pressure pulses to improve sterilization efficiency. This autoclave model achieves effective sterilization of complex instruments and porous materials by allowing steam to penetrate thoroughly.

The latest large autoclaves feature sophisticated control systems that enable users to accurately track the autoclave’s temperature, pressure levels and sterilization duration. The control systems help maintain uniform and reliable sterilization cycles.

Modern large autoclaves offer digital displays which deliver immediate updates during the sterilization process to enhance user interaction. Staff members can easily operate the autoclave and track its performance through straightforward navigation interfaces.

Users can choose precise sterilization parameters through automated cycle programs that adapt to different material types. The feature increases operational efficiency while maintaining uniform outcomes during multiple sterilization cycles.

Large autoclaves with data logging capabilities maintain detailed records of sterilization cycles which support compliance requirements and quality assurance processes. Healthcare facilities require this feature to meet their regulatory compliance obligations.

To achieve proper sterilization results it is essential to load the autoclave correctly. Arrange items in the autoclave so steam can move easily between them and place the heavier items at the bottom of the chamber. Do not pack the chamber too tightly because it can block steam from reaching all surfaces which results in proper sterilization failure.

To achieve the best performance from large autoclaves they must receive consistent maintenance and calibration. Perform routine inspections to assess equipment wear and tear while confirming that both temperature and pressure settings remain accurate.

Autoclave operators need proper training to ensure safety and effectiveness. Staff members must understand autoclave features alongside appropriate loading methods and required safety procedures to maintain effective and secure sterilization processes.

Set up a consistent validation process for testing the performance of sterilization cycles on a regular basis. Physical monitoring along with chemical and biological indicators must be employed to confirm autoclave functionality.

The extreme conditions of autoclaving cannot be tolerated by every material type. The compatibility of instruments and materials with autoclave sterilization must be understood to avoid damaging them.

The sterilization process becomes ineffective when air removal is insufficient because steam cannot penetrate adequately. The effective operation of the autoclave alongside proper air removal is essential for successful sterilization.

Sterilization protocols require consistent adherence which proves difficult in fast-paced healthcare settings. Continuous observation and record-keeping are essential for maintaining compliance with industry standards and legal requirements.

Healthcare facilities need to ensure sufficient space is available for both the installation and operation of large autoclaves. Healthcare facilities need to provide enough space for these devices to operate and ensure safe procedures for loading and unloading.

Healthcare settings rely on large autoclaves to maintain the sterility of medical instruments and equipment. When medical device distributors and procurement specialists gain knowledge about large autoclave types and usage practices they can select sterilization equipment based on informed decisions. The use of effective sterilization protocols enhances patient safety while also leading to better healthcare outcomes.

We welcome any inquiries about large autoclaves and sterilization best practices.

The primary function of a large autoclave is to sterilize medical instruments and equipment using high-pressure steam to eliminate harmful microorganisms.

When choosing a large autoclave, consider factors such as the volume of items to be sterilized, the types of materials being processed, and available space. Horizontal autoclaves are suitable for bulkier items, while vertical models are ideal for limited spaces.

Large autoclaves should be maintained regularly, with routine inspections and calibrations recommended at least once a year. However, more frequent checks may be necessary depending on usage.

生物学的インジケーターは、既知の量の耐性芽胞を導入することにより、滅菌サイクルの有効性を検証するために使用される。オートクレーブが正しく機能していることを確認するために不可欠です。

すべての素材がオートクレーブの高温・高圧に耐えられるわけではありません。滅菌前に器具と材料の適合性を確認することが重要です。

お問い合わせ先 inquiry@shkeling.com またはWhatsAppでご連絡ください。 +8618221822482.詳しくはウェブサイトをご覧ください: ケリング・メディカル.

無菌状態は、医療規制基準を満たしながら患者を保護するために、歯科診療所の基本であり続けています。歯科医院は、危険な微生物を根絶する器具や機器の滅菌にオートクレーブを使用しています。

歯科用器具や器材の無菌状態を維持することは、患者を保護し、衛生基準を遵守するために依然として不可欠です。歯科用滅菌器は、歯科用器具や器材から危険な微生物を除去するために不可欠な機器です。

歯科医療分野では、患者の安全を確保し、医療規制の基準を満たすために無菌環境が必要です。歯科用オートクレーブは、歯科器具に付着した有害な微生物を破壊する滅菌専用機として機能します。

無菌環境を維持することは、医療や製造業などにおける安全性と規制遵守のために不可欠です。工業用オートクレーブは、高圧蒸気を利用した高度な滅菌システムです。

医療分野では、何よりも効率的な滅菌方法が求められます。大型オートクレーブは、危険な微生物を除去することで、医療器具や機器の無菌性を維持します。これらの装置は、大量の