Mushroom crops face destruction when contaminated by bacteria, mold, or competing fungi. High-pressure steam in mushroom autoclaves removes pathogens to maintain substrate sterility for mushroom growth.

Financial losses occur when contamination leads to mushroom batch failures. Growers and distributors see better ROI when they use strong mushroom sterilizers to reduce contamination risks.

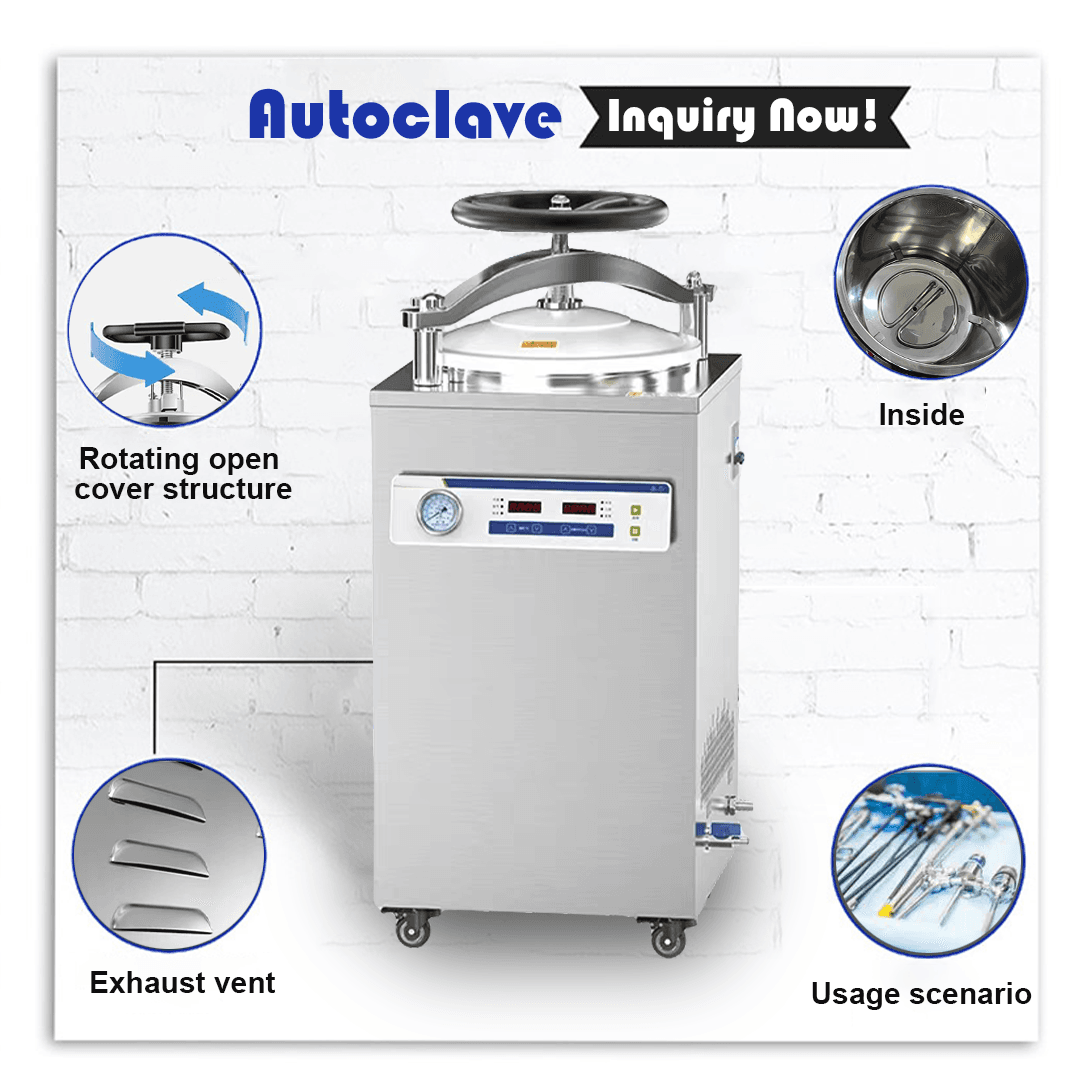

Mushroom Autoclave Systems:

Destroy microorganisms and spores by operating at 121°C and 15 PSI.

This system works well for medium and small substrate batches that fit into polypropylene bags or glass jars.

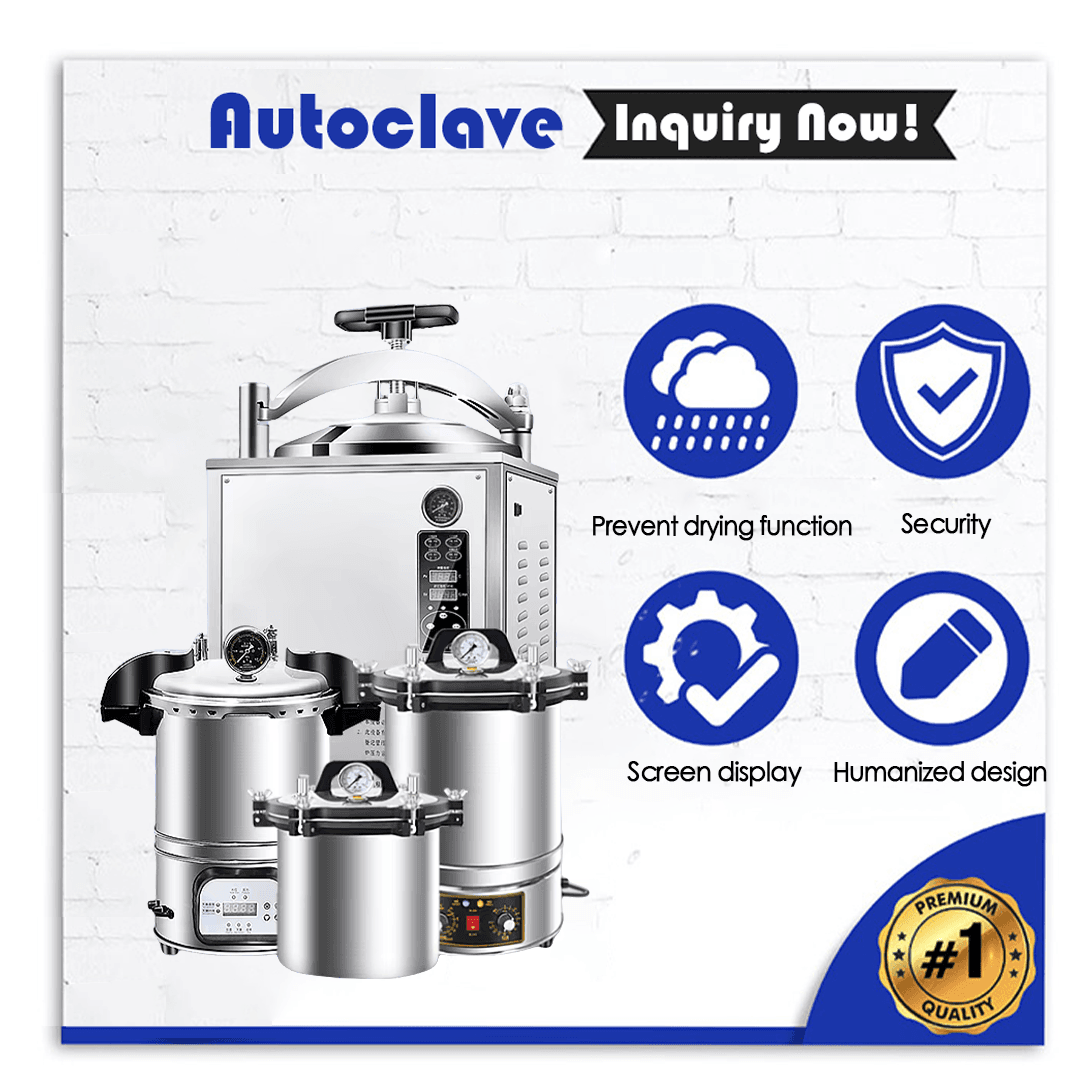

Atmospheric Steam Sterilizers:

Using steam at atmospheric pressure achieves bulk substrate sterilization in an economical manner.

Suitable for large-scale mushroom cultivation facilities.

Mushroom Substrate Sterilizers:

These machines are built to process organic materials such as straw, sawdust or grain.

Programmable cycles enable the system to manage different densities of substrates.

Pre-Sterilization Preparation:

Clean substrates thoroughly to remove debris.

Mushroom tools including pH testers are necessary to maintain optimal substrate conditions.

Cycle Optimization:

Set autoclave mushroom sterilization parameters such as time temperature and pressure levels according to the specific substrate being used.

Monitor with built-in sensors to prevent under/over-sterilization.

Post-Process Handling:

After sterilization move substrates into laminar flow hoods to protect against airborne contaminants.

Store in sterile containers until inoculation.

By integrating a high-pressure mushroom autoclave and enforcing strict sterilization measures a European mushroom farm achieved a 92% reduction in shroom contamination rates. The return on investment occurred after eight months because of better yield consistency.

AI technology powers automated sterilization cycles that adjust pressure and temperature controls dynamically.

Atmospheric steam sterilizers ensure sustainability through energy efficiency and reduced water usage.

The proper functioning of mushroom autoclaves along with substrate sterilizers remains essential to create sterile conditions for mushroom growing. Distributors can fulfill the expanding demand for dependable sterilization solutions with advanced mycology equipment investments such as atmospheric steam sterilizers and contamination-resistant mushroom tools. Advanced sterilization technologies deliver higher product quality while meeting the strict hospital and laboratory sterilization requirements.

Q1: How does a mushroom autoclave differ from a standard lab autoclave? A1: Mushroom autoclaves are optimized for organic substrates, offering larger chambers and moisture control features to handle materials like grain or straw.

Q2: Can atmospheric steam sterilizers replace autoclaves? A2: While effective for bulk processing, they lack the pressure required for rapid spore elimination. A hybrid approach is often ideal.

Q3: What substrate for shrooms is most prone to contamination? A3: Nutrient-rich substrates like grain spawn require meticulous sterilization due to their susceptibility to bacterial growth.

Q4: How do I maintain a mushroom sterilizer? A4: Regular descaling, gasket inspections, and calibration ensure longevity. Always follow the manufacturer’s maintenance schedule.

For inquiries about industrial-grade mushroom autoclaves, substrate sterilizers, or customized mycology equipment, reach out to our team:

Email: inquiry@shkeling.com

WhatsApp: +8618221822482

Website: https://autoclaveequipment.com/

Sterile conditions remain fundamental in dental practices to protect patients while meeting health regulatory standards. Dental clinics rely on autoclaves to sterilize their instruments and equipment which eradicates dangerous microorganisms.

Maintaining sterile conditions for dental instruments and equipment remains essential to protect patients and comply with health standards. Dental sterilizers serve as essential equipment that removes dangerous microorganisms from dental

The dental field requires sterile environments to ensure patient safety and to meet health regulation standards. Dental autoclaves serve as dedicated sterilization machines that destroy harmful microorganisms on dental equipment

The healthcare and manufacturing industries require sterile environments to ensure safety and meet industry standards. Industrial autoclave machines serve as sophisticated sterilization devices which use high-pressure steam to sanitize medical

Maintaining a sterile environment is essential for safety and regulatory compliance in healthcare and manufacturing industries among others. Industrial autoclaves represent sophisticated sterilization systems that utilize high-pressure steam to eradicate

The healthcare sector demands efficient sterilization methods above all else. Large autoclaves maintain the sterility of medical instruments and equipment by eliminating dangerous microorganisms. These devices manage substantial loads of