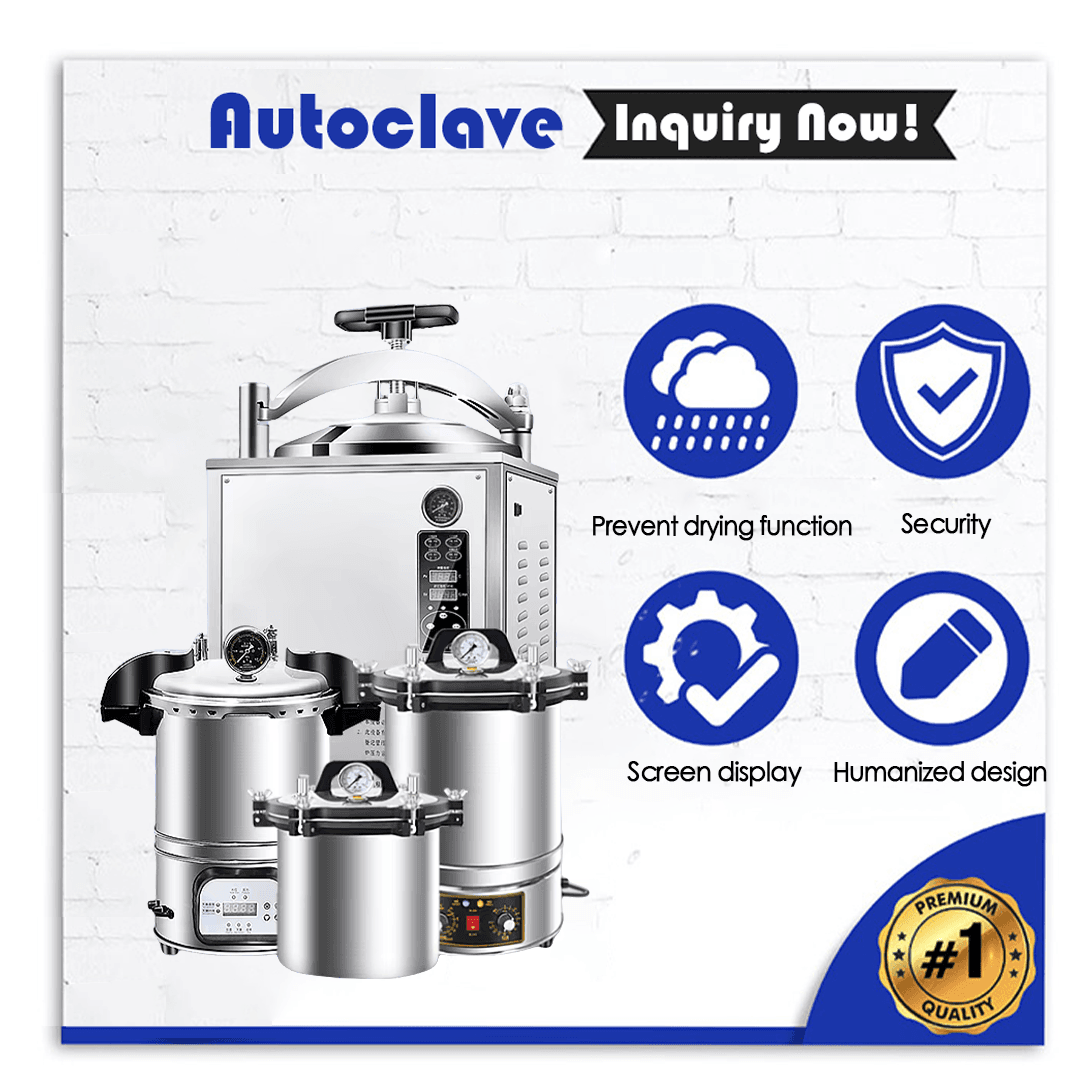

An autoclave functions primarily to sterilize medical instruments, lab equipment, and various materials completely. The proper arrangement of items in an autoclave facilitates complete steam penetration across all surfaces to ensure effective sterilization. When items are packed too tightly or placed incorrectly inside an autoclave they block the steam from reaching every surface which results in unsterilized areas that could cause infections. When distributors and procurement professionals stress correct loading techniques they enable their clients to keep superior hygiene levels while avoiding expensive procedural mistakes.

The autoclave can experience mechanical complications or its useful life can be shortened when items are loaded incorrectly into the machine. Blocking vents or sensors through improper placement of items creates a disruption in the pressure and temperature balance needed for effective autoclave operation. Dealers can protect their clients from unnecessary maintenance expenses while ensuring their sterilization systems remain reliable over time by teaching them proper autoclave loading procedures.

Sterilization practices in healthcare facilities are governed by rigorous regulatory standards. Inadequate loading of an autoclave can cause sterilization failures that lead to regulatory violations and subsequent penalties. By guiding clients on proper loading techniques distributors become trusted partners who help clients meet regulatory standards and increase their importance in the medical supply chain.

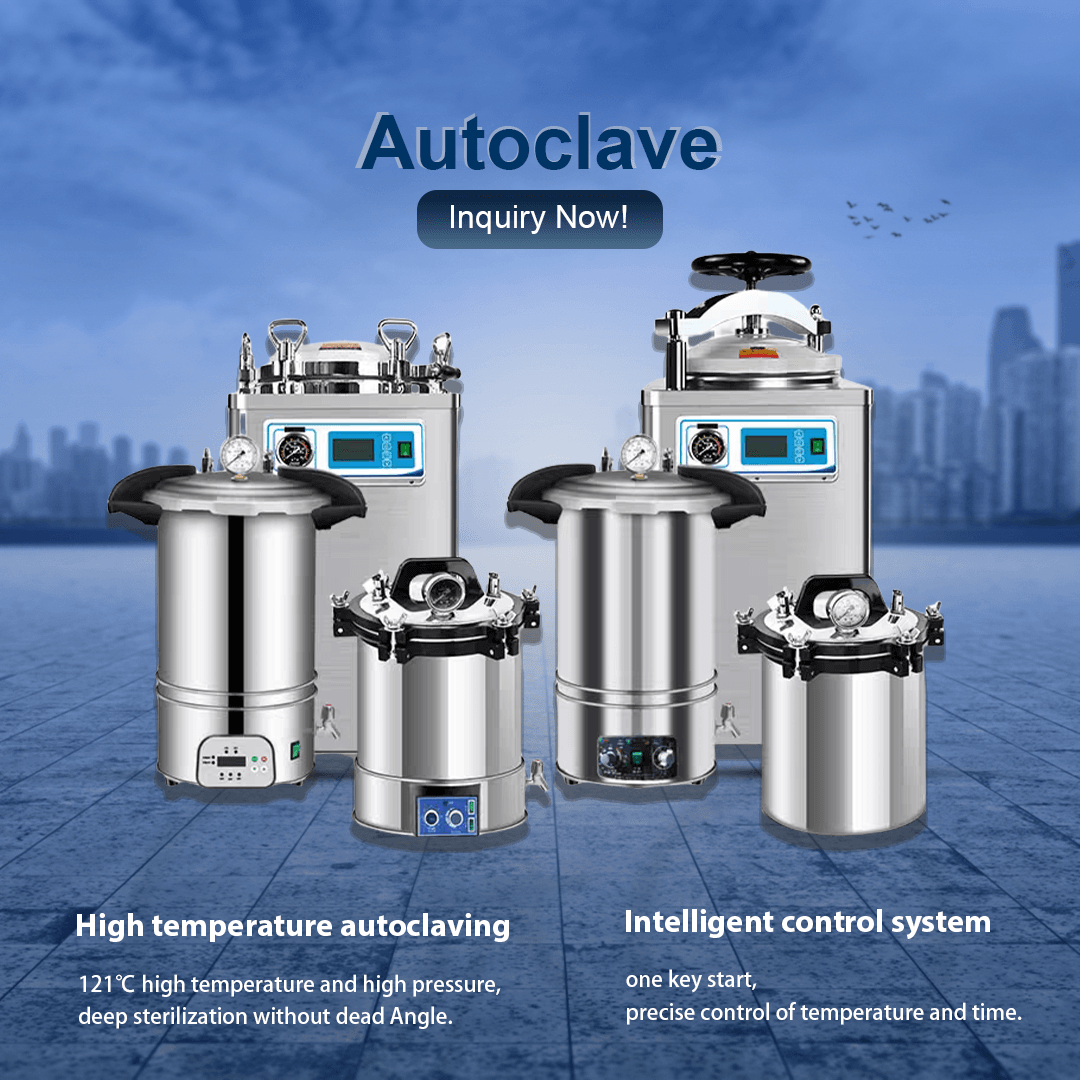

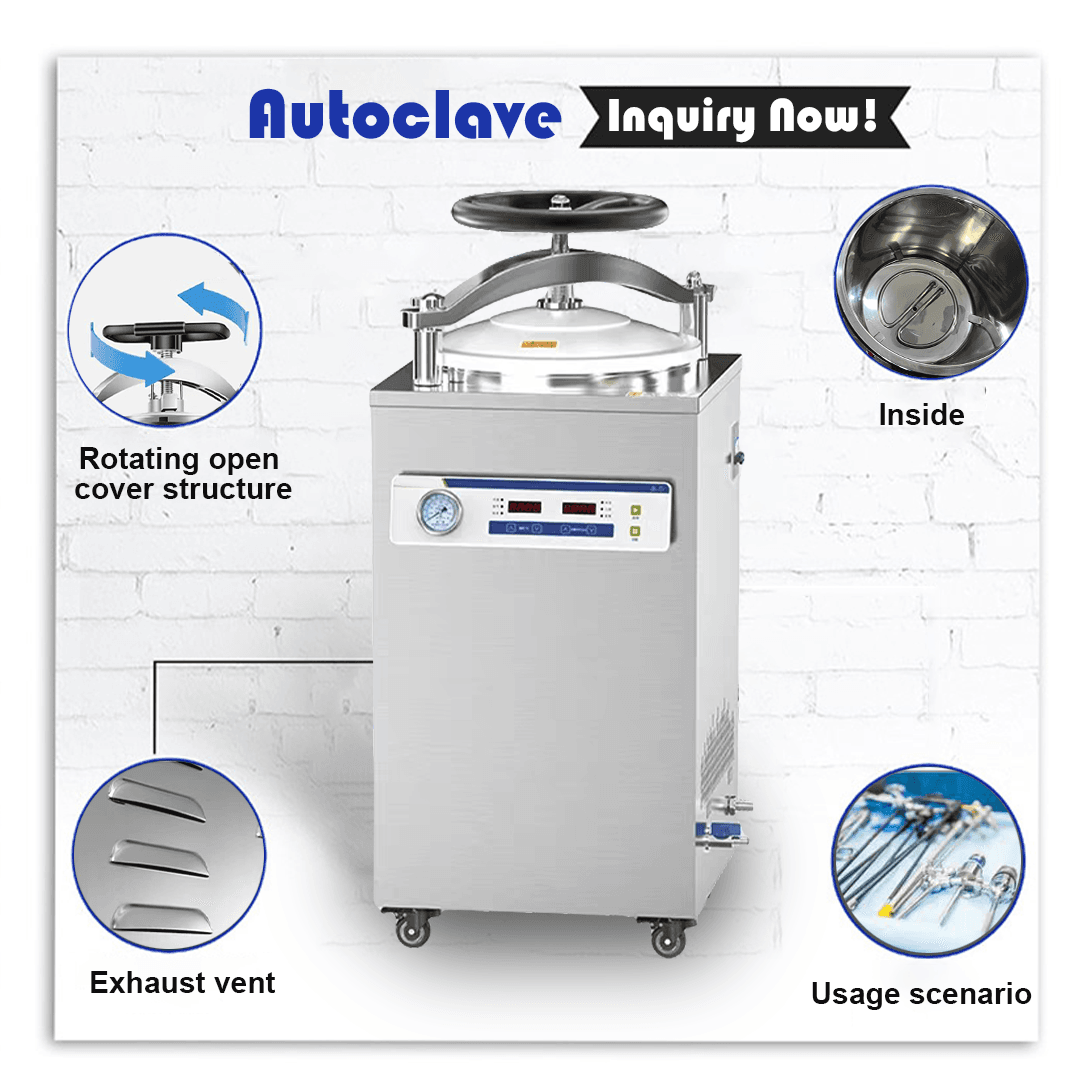

Autoclave chamber configurations are specifically designed to facilitate steam circulation before any detailed loading techniques are examined. Every unit features either trays, racks, or shelves to store items that work together with vents or ports to permit steam entry and air removal. Knowing how the autoclave chamber is structured enables users to place items in a way that ensures maximum steam exposure. Procurement specialists utilize their understanding of autoclave designs to suggest equipment with user-friendly loading features for their clients.

The most essential guideline for autoclave loading requires operators to refrain from filling the chamber beyond its recommended capacity. If the autoclave chamber becomes overcrowded steam circulation becomes restricted which results in cold spots that prevent proper sterilization. The chamber should stay filled at no more than 75-80% of its total capacity so steam can move freely around each item. Equipment distributors should guide their clients to evaluate their sterilization requirements and choose capacity-suitable equipment to avoid exceeding the limits of smaller autoclave units.

Load the items inside the chamber so steam can reach every surface. To ensure effective steam penetration it is important not to stack items directly atop each other unless using perforated trays or racks that allow steam access. Heavier and bulkier items belong at the chamber center or bottom area where steam tends to concentrate while lighter items should go on top trays. Dealers can make the process simpler for their clients and achieve reliable outcomes by supplying visual guides or loading diagrams.

The positioning of containers like glassware and sterilization pouches during loading operations is essential for proper function. Containers need to be positioned upright or tilted slightly to avoid trapping air that could obstruct steam penetration. Loosen lids or caps on containers to permit steam entry while placing pouches with their permeable side upward or away from the center to enable effective sterilization. Procurement professionals should teach clients about these minor yet effective details when showing them how to operate equipment.

Autoclaves usually include trays, baskets or dividers as accessories to optimize the loading process. The utilization of these devices ensures separation between items while preventing contact which leads to uniform steam distribution. Certain systems feature specialized holders to protect delicate instruments from damage throughout the sterilization cycle. Distributors can enhance their offerings by including these accessories in equipment packages or by advising clients on compatible add-ons that meet their specific requirements.

The process of loading liquids or biohazardous waste for sterilization requires unique considerations. When sterilizing liquids place them in heat-resistant containers with partially opened caps to avert pressure buildup and explosion risks. Autoclavable bags or bins containing waste materials must remain unfilled to allow steam penetration. Dealers have the responsibility to teach clients about proper loading techniques that maintain safety while processing various materials.

All items must be clean and free from visible debris prior to loading. When residual organic material remains on items it creates a shield that protects pathogens from steam exposure thus lowering the sterilization effectiveness. When feasible, items must be disassembled so that steam can penetrate hidden spaces within multi-part instruments. Distributors should stress that pre-cleaning is essential for proper loading procedures which demands thorough preparation.

Not all materials are suitable for autoclaving. The autoclave process could potentially harm items that react negatively to heat or moisture including specific plastics and electronic devices. Examination of material compatibility guidelines before loading is essential to protect equipment and ensure effective sterilization. Procurement specialists assist clients by supplying compatibility charts and reference materials which help simplify this process.

Organize chamber contents by considering each item’s size specifications along with its shape and construction material. Keep items separate using trays or racks but ensure steam vents and sensors remain unobstructed. Position packages or containers to maximize steam exposure while preventing larger items from obstructing smaller ones. Dealers who provide practical training sessions about strategic arrangement enable clients to become proficient in this essential loading element.

Complete item placement by checking distribution to ensure all areas remain uncrowded. Reposition items as necessary to maintain uniform spacing and allow proper steam access. With larger loads or mixed materials, this step becomes especially crucial. Distributors should motivate clients to use a checklist system for load distribution verification before beginning each cycle.

Securely close the chamber door or lid after loading to maintain the necessary pressure and temperature for sterilization. Check that all safety locks and mechanisms are activated to prevent unexpected openings during operation. Securing the chamber correctly represents the essential final step in loading and procurement professionals should emphasize its significance for safety and effectiveness to clients.

This article examines frequent errors made during autoclave loading while providing guidance to prevent these mistakes.

Sterilization effectiveness often suffers from the common mistake of overcrowding the autoclave chamber. Clients must process items in multiple cycles when needed instead of attempting to load everything into one sterilization cycle. Distributors should suggest sterilization equipment that features increased capacity or modular features to meet high-demand facilities’ needs.

Flat placement of items or positioning that traps air can block steam from accessing all surfaces. Training clients in proper orientation techniques like maintaining containers upright and keeping pouches open can help resolve this problem. Dealers distribute educational videos and materials that demonstrate correct placement procedures.

The balance of trays or racks becomes disrupted by uneven weight distribution which can cause items to move during the cycle and obstruct steam flow.

Healthcare facilities must adhere to rigorous hygiene and sterilization standards without exception. Medical equipment distributors and procurement professionals must understand the tools that maintain standards to deliver value to healthcare

Maintaining sterile medical tools and equipment stands as the most important practice for preventing infections and ensuring patient safety in healthcare settings. Medical equipment distributors along with dealers and procurement

The fast-paced healthcare sector operates under strict regulations which demand that sterility maintenance stands as a primary concern to protect patient safety and ensure compliance with operational standards. Medical equipment

Sterilization equipment serves as an essential tool in healthcare settings to maintain cleanliness standards and protect patients. Medical equipment distributors together with dealers and procurement specialists need to know the

Autoclaves serve as essential components of sterilization processes in healthcare facilities through high-pressure steam to destroy pathogens on medical instruments and other materials. Medical equipment distributors and procurement specialists must

Healthcare environments must prioritize sterilization because it protects patients and staff by removing infectious pathogens from medical devices and materials. The autoclave stands out as one of the best tools